In short, YES, you should have a close/holistic understanding about:

- How to build a product.

- How to ship a product, clearly identifying the direct/indirect stakeholders and what matters to them.

- How to make your product globally available.

- How your product gets found, trialled, used and experienced END TO END.

- Proactively de-risking your build to go-to-market end to end, effectively increasing the value of your operations and value chain.

Skipping this part means you lose opportunities for:

- Creating better partnerships.

- Personalising engagements and experiences that make people want to promote your solutions.

- Eliminating points of friction that drive better experiences as users learn, access and use your solution.

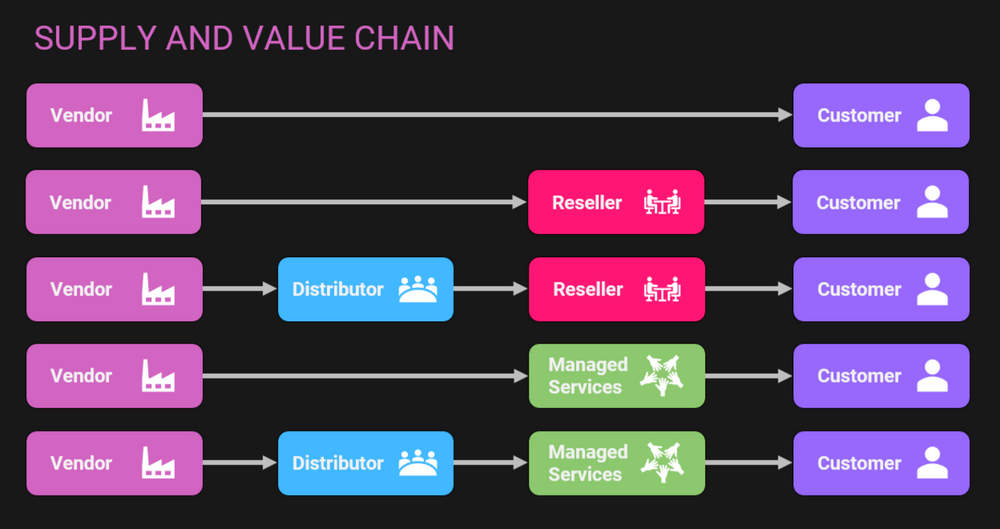

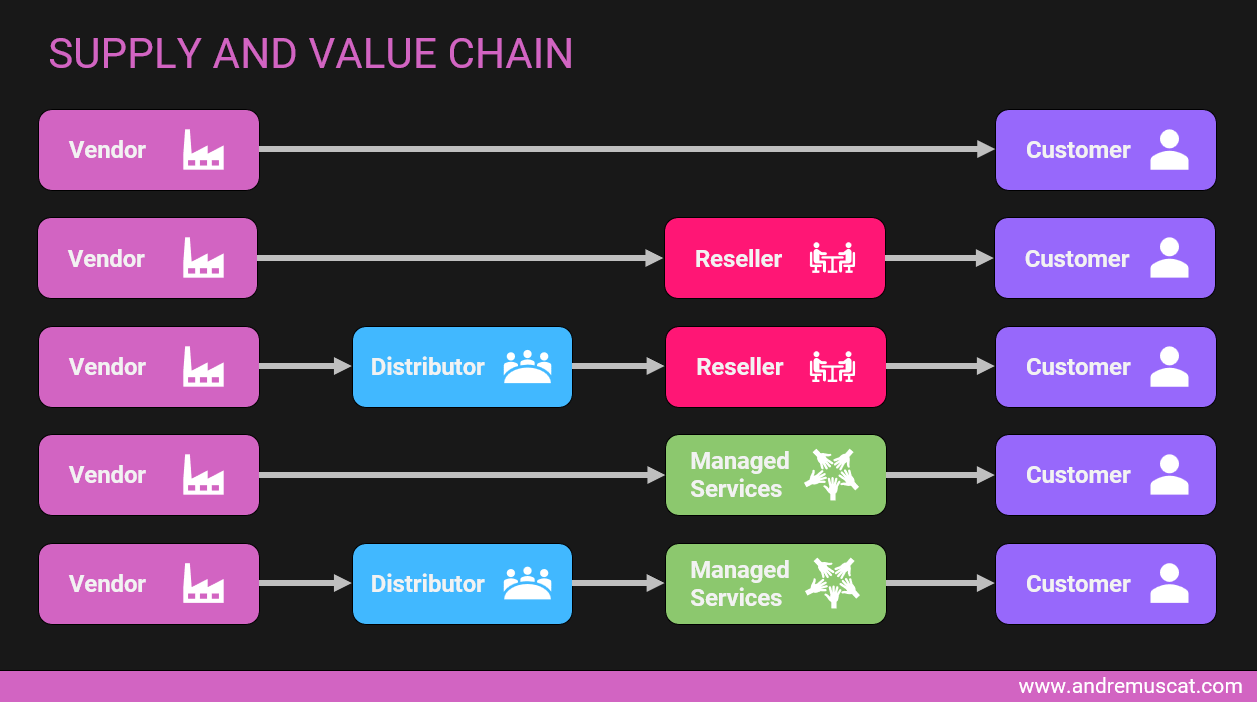

First things first - What is the supply and value chain?

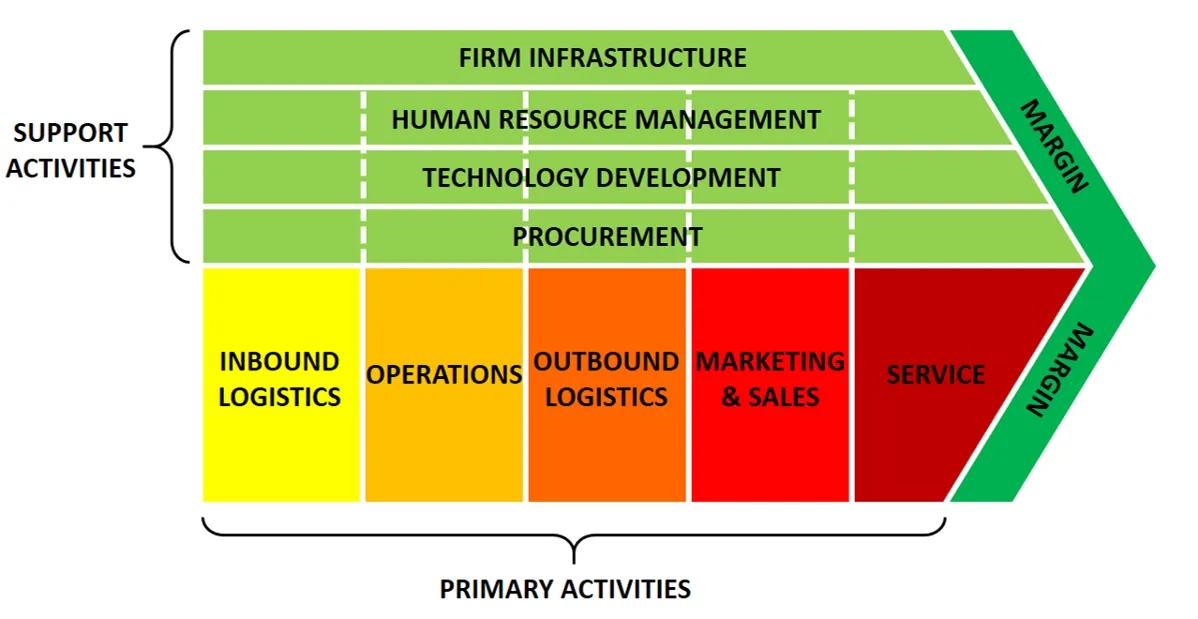

Supply and value chains deal with the way your business thinks about the sourcing of the raw materials, the production of your product(s), to the networks and partnerships that need to be managed to facilitate the delivery of the end product to your end customers.

The more efficient your supply and value chain management process is, the lower your production and delivery costs are, enabling your business to be more successful.

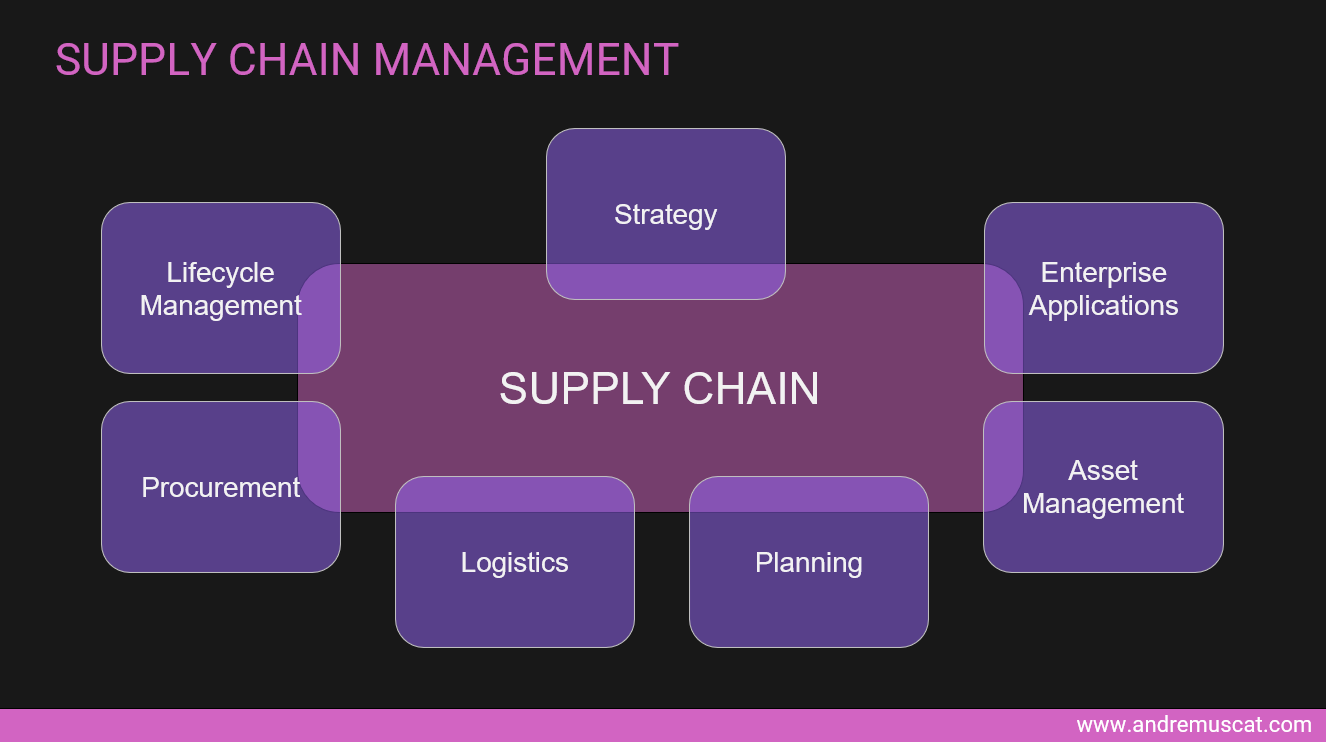

While operations management focuses on the activity to build and manage inventories, supply chain management looks at the interactions across the company and deals more with end to end strategy, facility location, product flow, transportation decisions and other logistics.

A quick reference to Tesla Giga Factories

Using the Tesla Giga Factory as an example, they recently released two new factories - One in Germany and another in Texas, USA.

You can observe the heavy investment Tesla made to improve efficiencies within its ability to build new factories using predictable efforts and timelines that result in repeatable capabilities made available globally. This means they have factored in a model of production that can sustain:

- Changing nature of customer/supplier relationships and alliances;

- growth and use of the Internet to facilitate e-business

- significant reductions in staff requirements through automation;

- focus on strategic goals related to cost/value#

- evolving supply chain management as an integrated competitive business advantage

For you, this means their product teams not only needed to understand the cars and stakeholders they were building for. They also needed to understand a broader set of processes and stakeholders that would be able to make and ship any of the future models to be made, shipped, ordered etc., through those factories. This means Tesla fully understood they have two key product components:

- The production environment (factory).

- The deliverable product (car).

- The value and supply chain that links all of the above.

The communications, licensing models, cost structures, and stakeholders are entirely different as you navigate the various facets of your supply chain.

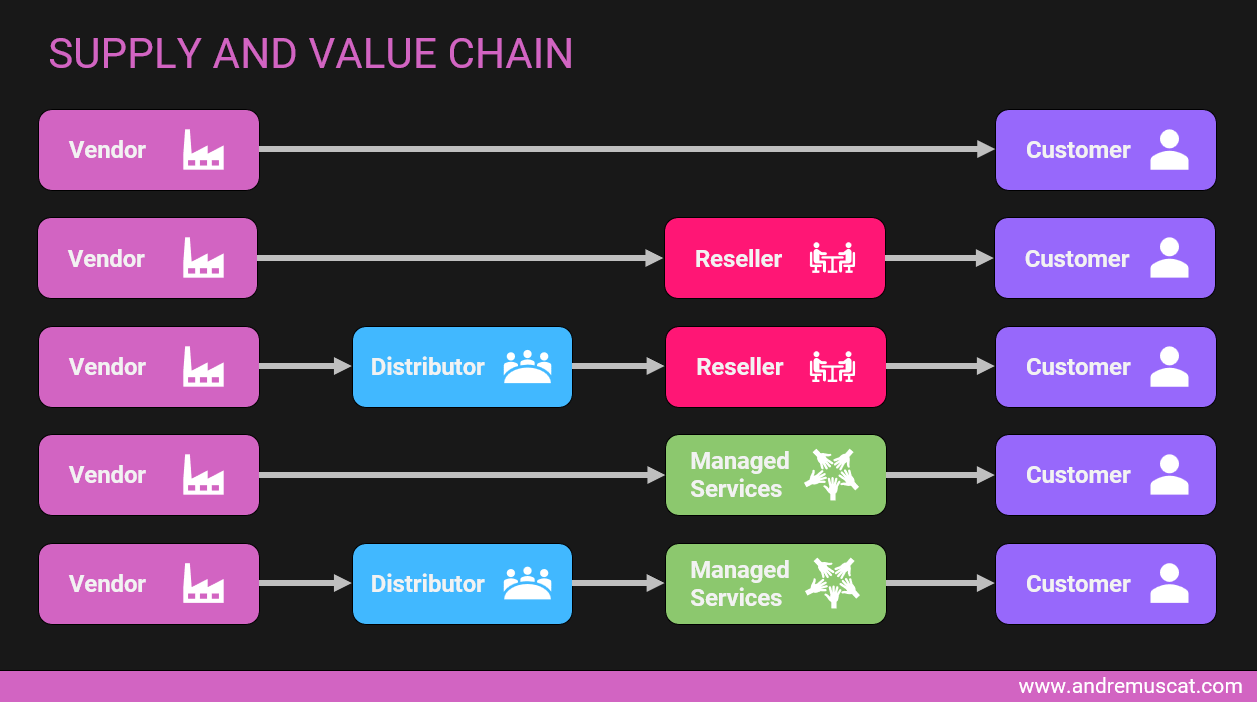

Software value and supply chain

Using an example in digital software, we typically deal with the following supply chain models:

This then changes further in box-shifters etc.

The more you understand who is involved in your go-to-market, you can then understand what your product is, i.e. the unity of all experiences, interactions and processes through which a customer experiences, promotes and licenses your product offering.

You need to be aware of critical trends, e.g.:

- Move towards centralised procurement/logistics and tracking of costs.

- Rationalisation of the supply base to a small set of strategic suppliers that can offer better costs at better conditions.

- Outsourcing the procurement of non-strategic items.

- Stress on real-time response to customer requirements.

- Greater emphasis on better forecasting, sales and operations planning and information sharing across the supply chain.

- Increasing pressure to reduce costs and demonstrate credible cost savings.

- Rising bar in terms of skills and training desired in supply management professionals.

- Growing emphasis on certifications and training for procurement professionals

What this means for you

Possessing a good understanding of these will bode well with you when entering the industry and taking on more complex projects. For the avoidance of doubt, understanding the value and supply chain is complimentary to your knowledge of;

- Project management

- Technical understanding

- Cost accounting skills

- Ability to understand financial statements

- Understanding of e-business/e-procurement systems

- Troubleshooting, problem-solving

- Knowledge of cross-cultural/global issues

- Business ethics

- Understanding of the legal issues involved in managing contracts

It's also important to possess good soft skills and personality attributes required in future supply managers which include:

- Ability to communicate effectively through presentations, email, one-on-one, and team discussion

- Ability to logically organise thoughts

- Ability as a natural facilitator to enable team-based decisions

- Time management

- Leadership

- Understanding customer's expectations

- Vision – creating the environment

- Desire to learn

- Ability to present oneself with confidence

- Ability to think on one's feet

- Ability to pass on knowledge and mentoring

In the end, any production line (physical, virtual, data, software etc. has a poster child to reference through Tesla):

In conclusion

Think ahead! Think holistically!

As we become better and more focused on eliminating friction across the value and supply chain, more focused roles will inevitably evolve around these competencies.

The onus will start on the CEOs and boards that need to ensure that their companies move in the right direction of investment returns and efficiencies.

NOTE: Views are my own, based on my observations and experiences. I believe in productive discourse and welcome opportunities to refine my understanding through discussion. Comment in the comments area below or reach out on hi@andremuscat.com